Modern Day Marine

By: Sam LichtmanPosted on September 8, 2022

Expo Features Display of Latest Innovations In Gear, Technology

By Sam Lichtman

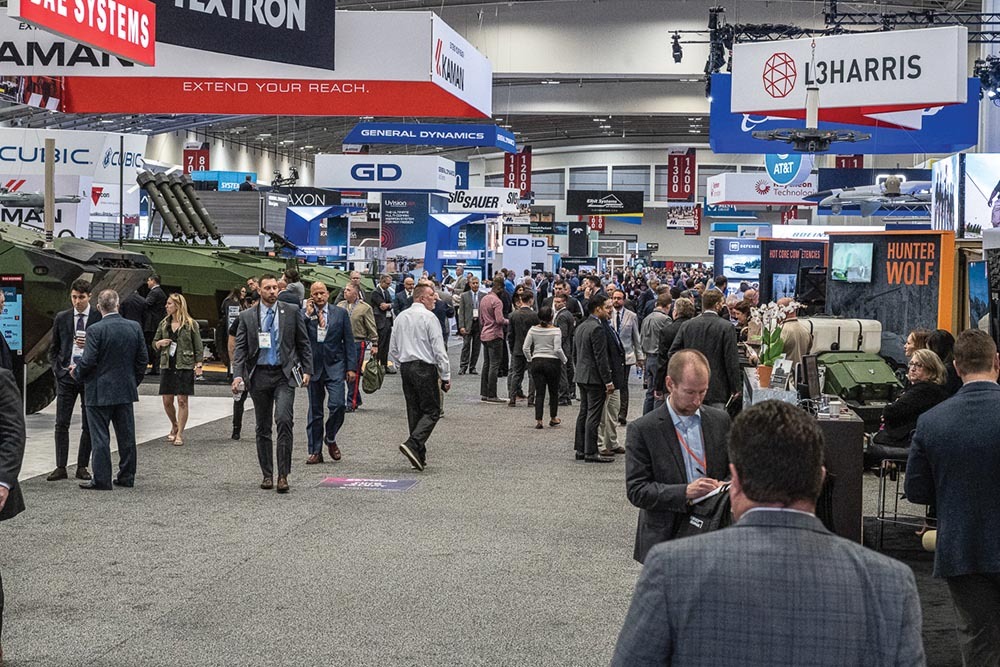

From May 10-12, representatives from more than 400 defense contractors, government agencies, and nonprofit organizations descended on the Walter E. Washington Convention Center in Washington, D.C., for Modern Day Marine (MDM) 2022, hosted by the Marine Corps Association (MCA) and the Marine Corps League (MCL).

In addition to the exhibitors, the MCA and MCL hosted a slate of guest speakers including the Secretary of the Navy, Carlos Del Toro; General David H. Berger, Commandant of the Marine Corps; and several other senior leaders of the Corps. Throughout the three-day expo, they delivered informative presentations on a wide variety of topics ranging from acquisitions to littoral combat. Of note were several briefings covering various aspects of Force Design 2030, Gen Berger’s plan to make the Marine Corps more flexible and adaptable. The briefings and guest speakers, a key component of MDM, provided an opportunity for professional development for the many Marines who attended the expo from throughout the National Capital Region.

Leatherneck sent representatives to the event to learn about the latest in military technology and offer our readers a sampling of what’s new in the industry. Future issues of Leatherneck and marinemilitaryexpos.com will have information about next year’s event, scheduled for June 27-29, 2023.

MCA offers more professional development resources at:

mca-marines.org/professional-development.

HDT Global Hunter WOLF

Unmanned vehicles seem to be a popular technology among some of the larger companies in the defense industry. Among others, HDT Global had two examples of their Hunter WOLF (Wheeled Offload Logistics Follower) unmanned ground vehicle on display. The Hunter WOLF is a small six-wheeled ground vehicle with a hybrid powertrain running on electricity with a diesel generator for charging the battery; it is designed to support an infantry squad in any terrain or climate. The vehicle’s compact dimensions allow it to be airlifted to combat zones; a V-22 Osprey is able to carry two of them and the Army’s CH-47 is able to carry six. Its modular design and 1-ton payload capacity allow Marines to convert the Hunter WOLF between a wide variety of configurations. HDT had one set up as a logistics vehicle and another with a remote weapons system at Modern Day Marine; other payload packages are designed for reconnaissance, engineering, and even anti-tank missions. The vehicle is controlled using a small wireless remote or can even be set to autonomously follow dismounted infantry.

The Hunter WOLF has seen use in the Australian Outback as a sort of robotic farmhand, allowing one remote operator to safely and comfortably perform the work of many people in less time. The Marine Corps is currently testing tethered quadcopters powered by the Hunter WOLF’s onboard generator. More information is available at hdtglobal.com/series/hunter-wolf/.

Oshkosh Defense/Pratt miller EMAV

Oshkosh Defense also brought an unmanned ground vehicle to the show. In development for six years by their subsidiary Pratt Miller Defense in conjunction with QinetiQ, the EMAV (Expeditionary Modular Autonomous Vehicle) is much larger and more than twice as heavy as the Hunter WOLF but retains a similar low profile. It travels on rubber tracks at more than 50 miles per hour over flat ground and can be carried internally aboard the V-22 Osprey and other military transport aircraft. The EMAV can be rapidly reconfigured in the field with more than 40 different mission packages and can carry up to 3 tons. Its software allows it to operate with many types of remote controllers or drive itself with varying levels of autonomy.

Like the Hunter WOLF, the EMAV is designed to support dismounted infantry by carrying supplies and providing electrical power even when no mission package is installed. While moving, its onboard generator can produce up to 3.4 kW of power on a low-voltage rail to charge batteries for optics, night vision devices, laser aiming modules, and other electronics Marines carry. While stationary, the EMAV can output up to 30 kW on its high-voltage rail to help power a small forward operating base.

Oshkosh has delivered four EMAVs to the Army and six to the Marine Corps, which are currently undergoing testing at the Marine Corps Warfighting Laboratory. The Army has been running the EMAV through its Robotic Combat Vehicle–Light (RCV-L) trials program. More information is available at https://www.qinetiq.com/.

Maztech Industries X4-FCS

Irvine, Calif.,-based engineering company Maztech Industries made a big splash this year with their X4-FCS device, a weapon-mounted ballistic computer. They brought two units to Modern Day Marine to show off their capabilities.

Developed in collaboration with Magpul, the X4-FCS consists of a ballistic computer integrated into a conventional 30 mm or 34 mm scope mount, designed for use with a low-power variable optic (LPVO) such as the Marine Corps’ new Squad Day Optic (SDO). Powered by two CR123 or four 18650 batteries, it projects a digital overlay into the objective lens of whatever scope is mounted to it to provide more information to the shooter at a glance. The X4-FCS can be programmed in the field with profiles for up to 25 different ammunition types; using atmospheric sensors, it can update its reticle in real time based on the exact ballistic characteristics of each round to show how far it will drop at a given distance. The unit can also sense its own pitch and roll to allow it to compensate for the angle at which the rifle is held. With an optional laser rangefinder attached, the X4-FCS can even display a marker to show exactly where to aim to hit the target—all without the shooter taking his or her eye off the target.

The modular design of the X4-FCS makes it compatible with any rifle scope of the correct size and allows different electronics packages to be added on if newer optical devices, such as better sensors and rangefinders, are ever developed. Maztech is currently working with Magpul on a “smart” magazine which will count the number of rounds inside and tell the X4-FCS what type of ammunition is loaded so it can automatically adjust the reticle for different ballistic properties. To learn more, check maztechindustries.com/x4-fcs.

Magpul Industries

Magpul had a large display this year with many of their new and popular civilian products. Since 2016, a variant of its PMAG GEN M3 has been approved by the Marine Corps as a replacement for old Colt-pattern aluminum “G.I.” magazines to feed the M16A4, M4, and M27. In fact, the updates made between the second generation and current third generation of PMAG included a change to the shape of the magazine body to allow compatibility with platforms such as the M27 IAR. Additionally, the PMAG GEN M3 was designed with different feed geometry to present the rounds at a higher angle, allowing use of the M855A1 EPR (Enhanced Performance Round) without damaging rifles’ feed ramps.

Magpul has been producing the PMAG for decades and the Marine Corps has been issuing it as standard equipment for several years; given its excellent track record for reliability in harsh conditions, it appears that the PMAG is here to stay. For more information on Magpul’s new products for this year, check magpul.com/what-s-new.html.

Blue Force Gear

A longtime favorite among military riflemen and civilian shooting enthusiasts across the country, Blue Force Gear had some excellent products to show off at their booth at Modern Day Marine this year. The company already supplies two products to the U.S. military: their famous Vickers sling and a holster for the M320 grenade launcher. Blue Force Gear doesn’t just cut fabric and run sewing machines; they actively work to develop some of the most technologically advanced load-bearing equipment on the market. Their CHLK two-belt system, for example, is advertised to weigh 50 percent less than competing battle belts and is angled and contoured to fit around the wearer’s waist more comfortably with no break-in period.

To manufacture their load-bearing equipment, Blue Force Gear laser-cuts MOLLE-compatible attachment slots out of the material. This design has been gaining popularity in the industry because it allows manufacturers to use fewer pieces of material, making the finished product stronger and lighter.

Blue Force Gear’s website is packed with information on their products as well as the technology that makes them possible. You can learn more at blueforcegear.com/about_us.html.

Trijicon SCO

Trijicon has supplied riflescopes to the U.S. military since 1987 and shows no sign of slowing down. Hundreds of thousands of Marines have used the RCO [Rifle Combat Optics], a variant of the Trijicon ACOG [Advanced Combat Optical Gunsight] TA31F, since its adoption in 2005. Beginning two years ago, however, the Marine Corps has been replacing the RCO on its rifles and MGO [Machine Gun Optic] (another ACOG variant) on machine guns with Trijicon’s new Squad Common Optic (SCO). Whereas the RCO is a prismatic scope with a fixed 4x magnification, the SCO is a low-power variable optic with a magnification range from 1 to 8 power. While its smaller 28 mm objective lens gathers about 25 percent less light, the variable magnification and user-adjustable brightness make it more useful in both close-quarters and long-range engagements in a wider variety of environmental conditions. Trijicon’s representatives say the VCOG [Variable Combat Optical Gunsight] family, of which the SCO is a member, has the same rugged construction as the RCO and is guaranteed completely waterproof to 66 feet. It is also compatible with the same mounts as legacy Trijicon optics, making it a true drop-in solution for any weapons system already equipped with an RCO or MGO.

Trijicon also manufactures a wide range of sighting systems for the law enforcement and civilian markets, ranging from tritium-illuminated iron sights for pistols to long-range precision scopes for hunting and competition. For more information, visit trijicon.com.

Office of Naval Research H-TaRP

Without a doubt, the Office of Naval Research (ONR) had one of the most exciting displays on the show floor. They were demonstrating their hydrogen tactical refueling point (H-TaRP), a version of what they call an expeditionary hydrogen generator, developed with MIT’s Lincoln Laboratories. This device is designed to be used at the company level to produce hydrogen pressurized to 5,000 psi to fuel unmanned aircraft, drive fuel cells to generate electrical power, or inflate balloons to loft radio antennae or reconnaissance payloads. Waste heat from the chemical reaction can be used to cook food, dry wet clothing and perform other useful work.

ONR’s engineers describe the H-TaRP as functioning like a giant gumball machine: a hopper at the top dispenses pellets of specially treated aluminum, which fall down and react with water in the reaction chamber to produce hydrogen, heat and aluminum hydroxide. This is the same chemical reaction which takes place inside the flameless ration heater included in MREs. The aluminum can come from any source, even empty beverage cans, and is first “activated” by heating it to 200°F with a small amount of indium and gallium. Any water will work, even unfiltered seawater, and the leftover aluminum hydroxide is non-toxic.

Three variants of expeditionary hydrogen generator are currently in development: the company-level H-TaRP unit displayed at Modern Day Marine, a smaller version for use at the squad level, and an individual unit for charging batteries and other relatively low-power applications. H-TaRP is currently in testing with II MEF at Camp Lejeune, N.C., and can be carried and set up by two Marines in as little as 13 minutes after just an hour of training. For information on ONR and their programs, check their website at onr.navy.mil.

ONR’s TechSolutions program allows Marines and Sailors to submit requests to develop new technologies to solve specific problems encountered in the field. If the technology can be developed within 12 months and for less than $1 million, the TechSolutions office will work with a network of R&D centers to bring it to fruition. To learn more about the TechSolutions program, go to onr.navy.mil/techsolutions/about.html.

Author’s bio: Sam Lichtman is a college student and licensed pilot. He works part-time as a manager and armorer at a Virginia gun store and occasionally contributes content to Leatherneck. He also has a weekly segment on Gun Owners Radio.